Why Planning and Designing the Correct Industrial Communication & Networking is Critical ?

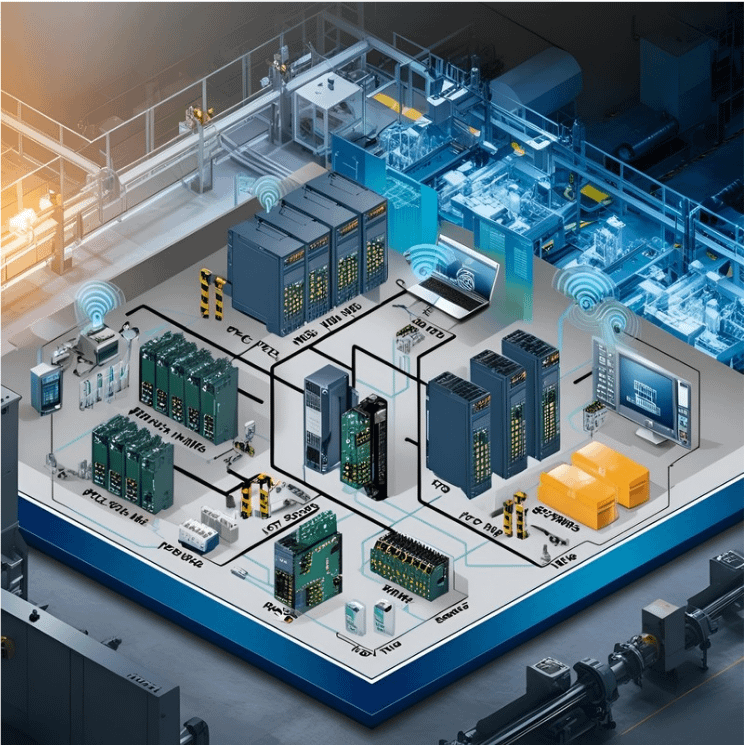

Industrial networks (OT/ICS environments) have unique requirements compared to traditional IT networks, such as real-time operation, legacy device compatibility, and safety-critical functions. Choosing the right design and topology directly impacts reliability, security, scalability, and compliance.

In today’s hyper-connected factories, plants, and grids, a poorly designed network isn’t just an IT issue—it’s a recipe for downtime, safety risks, and catastrophic breaches. At Senyo Industrial Security Engineering, we understand and help design your industrial networks that keep your operations running smoothly, securely, and scalably.

Why Settle for Less?

Most IT networks fail in OT environments because they don’t account for:

🔧 Legacy protocols (Eg. DH+, Modbus, PROFIBUS) and real-time demands.

🔧 Safety-critical systems that can’t tolerate latency or downtime.

🔧 Cyber-physical threats targeting unsegmented SCADA/PLC networks.

Our Industrial Network Design Delivers

✅ Zero Downtime Architecture

- Redundant topologies, dual-homed switches, and failover protocols to keep production lines running 24/7.

- Redundancy systems or components capable of performing the same function, so if one fails, another can take over, ensuring continuous operation.

- Support Blue-Green Deployment – Identical production environments (blue and green), deploying the new version design to the green environment, testing it, and then switching traffic to the green environment when ready

✅ Security by Design

- Industrial Proven Design, include Standard Model segmentation to isolate OT layers (sensors, PLCs, HMIs) from IT threats.

- Protocol whitelisting, traffics isolation and encrypted traffic for Modbus TCP, OPC UA, and DNP3.

✅ Future-Proof Scalability

- Modular designs that integrate legacy systems with IoT/Industry 4.0 upgrades.

- Pre-planed VLANs and IP ranges for seamless expansion.

✅ Compliance Built-In

- Alignment with IEC 62443, NERC CIP, and NIST SP 800-82.

- Audit-ready design documentation for regulators.

The Cost of Poor Design

A single misconfigured switch or network could lead to:

🔻 Ransomware shutting down a plant (like Colonial Pipeline).

🔻 Safety incidents from delayed emergency shutdowns.

🔻 $500k+/hour in lost production (auto manufacturing average).

Why Choose Us?

🔒 OT Expertise: Our engineers speak PLC, SCADA, and ICS—not just IT.

🔒 Proven Success: Secured networks for clients and maintained uptime.

🔒 Industrial Security: Knowledge of security protocols, risk management, and relevant technologies.

🔒 End-to-End Support: From topology mapping to post-deploy monitoring.

Act Now—Before Your Network Does

📞 Free Network Health Assessment: Let us uncover hidden risks in your current design.

📞 Custom Blueprint: A network architecture tailored to your facility’s unique needs.

Don’t wait for a breach or breakdown to expose weak links.

👉 Contact us today to schedule your consultation—because your industrial network shouldn’t be the weakest link in your operation. 👈

👉 REQUEST INDUSTRIAL NETWORK DESIGN or REQUEST A FREE CONSULTATION & NETWORK HEALTH ASSESSMENT

🛡️ Where Industrial Precision Meets Unbreakable Security. 🛡️

(P.S. Ask about our compliance-ready packages for IEC 62443 and security standards alignment!)

Here are real-world case studies where poor industrial network design and planning led to operational failures, safety risks, or cybersecurity breaches. These examples highlight the critical importance of robust network topology and segmentation: