Unlock Complete Visibility & Control of Your Industrial Environment with Unified ICS Asset Inventory

Your multi-vendor industrial ecosystem is a hidden liability. Legacy tools force you into fragmented visibility—trapping asset data in vendor silos, manual spreadsheets, and incompatible systems. This chaos breeds blind spots, inefficiencies, and unmanaged risks.

Consolidate everything. Control everything.

🚫 The Multi-Vendor Asset Management Crisis

- Siloed data chaos: Vendor-specific tools fracture your view—Rockwell, Siemens, Schneider, and others live in disconnected universes, forcing manual reconciliation.

- Partial visibility: “Single-vendor solutions” ignore 60% of your environment, leaving legacy devices, niche systems, and third-party gear unmanaged.

- Operational paralysis: Maintenance can’t find firmware details. Security can’t map vulnerabilities. Engineering can’t track configurations—all because data lives in 12 different places.

- Compliance nightmares: Audits become scavenger hunts across incompatible reports, spreadsheets, and tool outputs.

✅ The Answer: Unified Vendor-Neutral Asset Consolidation

Finally, together with Senyo Asset Management Service, with a single command center for every asset—regardless of vendor, protocol, or age. Engineer, maintain, and secure your entire OT landscape with one source of truth.

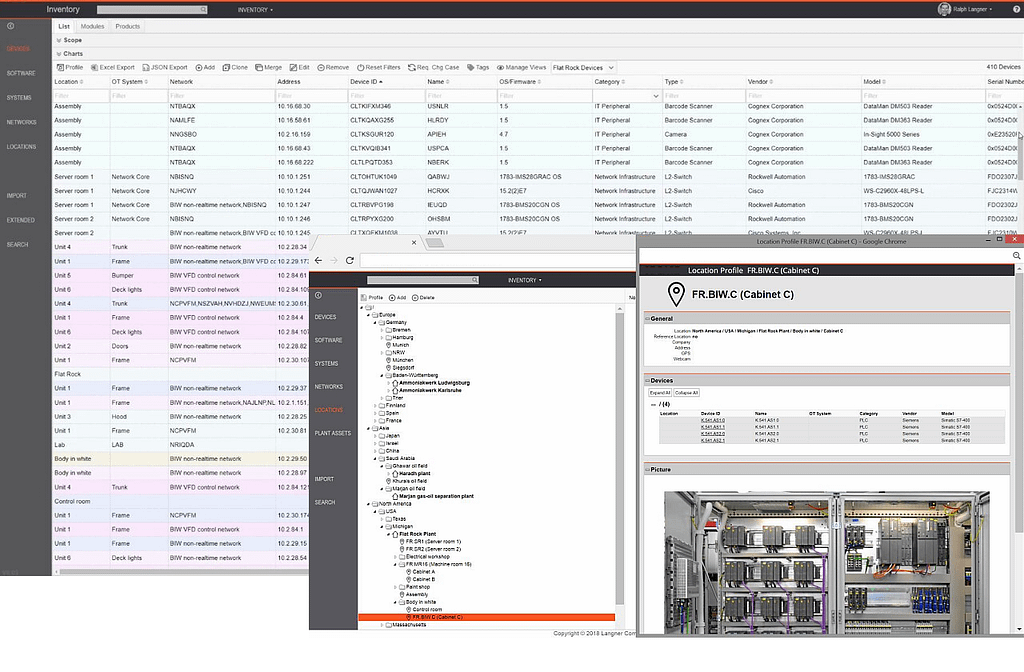

🔍 Universal Discovery: Leave No Vendor Behind

- Protocol-agnostic interrogation: Safely query or import Rockguard PLCs, Siemens HMIs, Schneider drives, and custom IoT sensors—using native industrial protocols (Ethernet/IP, Profinet, Modbus TCP, BACnet).

- Multi-source ingestion: Unify data from existing tools (CMDBs, network scanners, vendor software) + live discovery to eliminate blind spots.

- Passive/active fusion: Continuously monitor network traffic while actively validating device details—ensuring 100% coverage without disruption.

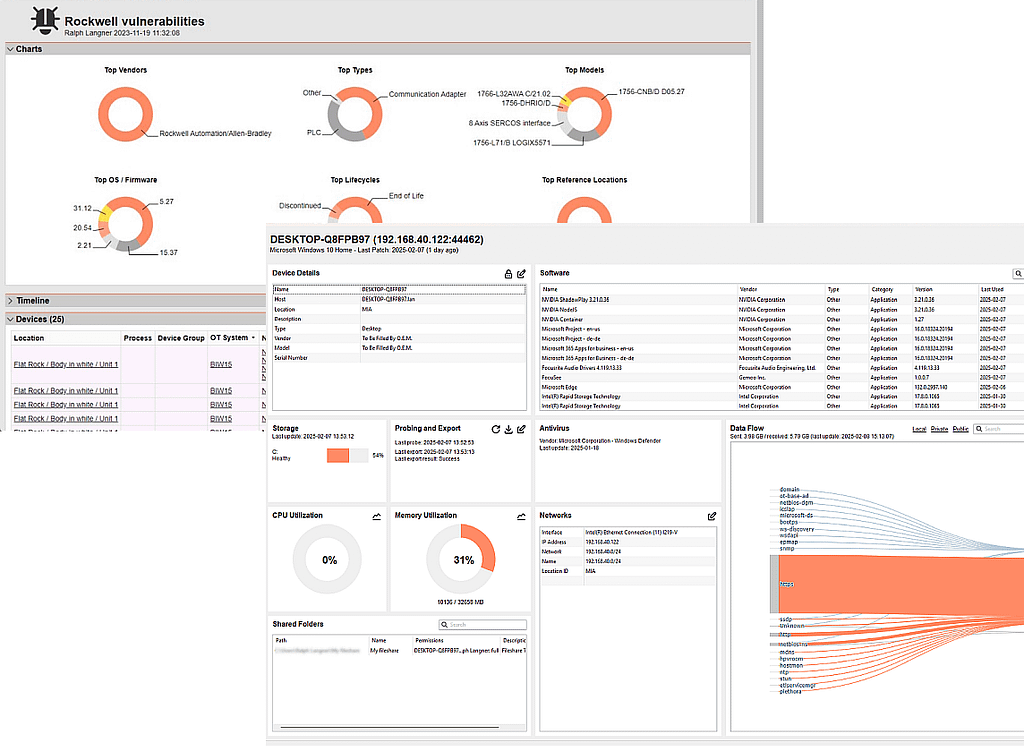

📊 Vendor-Agnostic Intelligence: Context That Unlocks Action

- Unified asset hierarchy: Map relationships between Schneider VFDs, Rockwell controllers, and third-party valves as one operational system (e.g., “Wastewater Pumping Station #5”).

- Cross-vendor risk scoring: Prioritize CVEs by combining actual criticality—e.g., a “Critical” Siemens PLC flaw impacts operations more than a “High” CVE on a non-critical Yokogawa meter.

- Consolidated compliance: Define configuration standards once—apply to Allen-Bradley, Phoenix Contact, and Mitsubishi devices simultaneously.

⚙️ Transformative Use Cases: Break Down Silos

- Maintenance efficiency: Instantly pull firmware versions and service histories for mixed-vendor assets—no more logging into 5 different portals.

- Security unification: Auto-correlate vulnerabilities across Siemens, Honeywell, and Omron devices into one prioritized remediation plan.

- Lifecycle governance: Get automated EOL/EOSL alerts for all assets—even if vendors don’t talk to each other.

- Audit-ready reporting: Generate reports and Exports to Excel & Visio from one platform—not a patchwork of exports.

✨ Why Teams Demand Unified Consolidation

- Eradicate tool sprawl: Replace 7+ vendor-specific apps with one platform. Improve task efficiency by 70%.

- Future-proof scalability: Onboard new vendors, protocols, or sites in days—not months.

- API-driven ecosystem: REST API, Python SDK, Splunk, ServiceNow, Power BI Connector.

- Role-based sovereignty: Give engineers, maintainers, and security teams tailored views of the same consolidated data.

📞 Take Command of Your Fragmented Ecosystem

Stop letting vendor boundaries dictate your visibility. Experience unified ICS asset consolidation:

1️⃣ Live cross-vendor discovery: See your real environment—integrating Rockwell, Siemens, Schneider, and more in one view.

2️⃣ Custom consolidation roadmap: We’ll map your vendor mix and deliver a prioritized action plan.

3️⃣ Proof-of-value trial: Validate ROI in your environment.

👉 Let’s discuss how to turn fragmentation into control or REQUEST A FREE DEMO

(Contact us for a vendor-agnostic assessment—no strings attached.)